Leave Your Message

-

Whatsapp

-

Whatsapp

In the ever-evolving world of construction and interior design, the demand for high-quality materials has surged, with Plywood Laminated Board emerging as a popular choice due to its versatility and durability. According to a report by MarketsandMarkets, the global plywood market is expected to reach $81.5 billion by 2025, with a significant portion attributed to the rising use of laminated boards in both residential and commercial applications. As builders and designers increasingly prioritize sustainability and longevity, selecting the right manufacturer of Plywood Laminated Board becomes crucial. This guide aims to equip you with the knowledge needed to navigate the myriad options available and identify high-quality products that cater to your specific project needs.

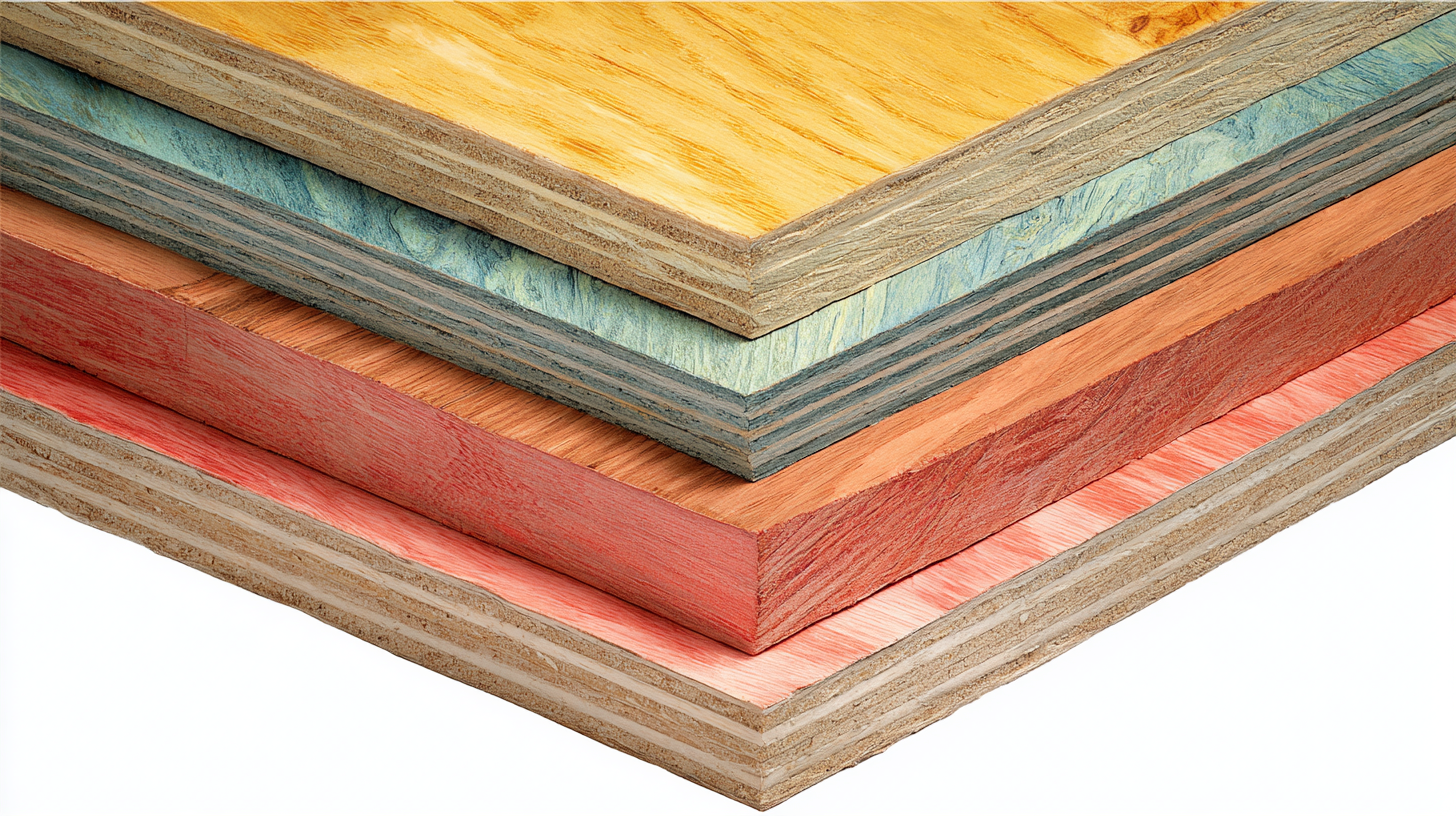

Plywood laminated boards have become increasingly popular in construction and furniture design due to their versatility and strength. These boards are engineered by bonding multiple layers of plywood together with a high-quality adhesive, resulting in a composite that resists warping and enhances durability. According to a recent report by MarketsandMarkets, the global plywood market is expected to grow significantly, reaching $80 billion by 2026, reflecting the rising demand for high-performance materials in various applications.

One of the key features of plywood laminated boards is their superior moisture resistance, making them ideal for humid environments. This characteristic is especially beneficial in kitchen and bathroom applications, where dampness can lead to structural damage. Additionally, these boards offer excellent aesthetics, with a variety of finishes that mimic solid wood, while being more cost-effective.

One of the key features of plywood laminated boards is their superior moisture resistance, making them ideal for humid environments. This characteristic is especially beneficial in kitchen and bathroom applications, where dampness can lead to structural damage. Additionally, these boards offer excellent aesthetics, with a variety of finishes that mimic solid wood, while being more cost-effective.

Tip: When selecting plywood laminated boards, always check the thickness and grade of the plywood used. Higher-grade plywood typically offers better overall performance and longevity.

Another advantage is their eco-friendliness. Many manufacturers are now using sustainably sourced wood and low-VOC adhesives, making these boards a responsible choice for environmentally conscious projects.

Tip: Look for certifications such as the Forest Stewardship Council (FSC) label to ensure you're choosing products that contribute to sustainable forestry practices.

China's plywood export industry has experienced significant growth in recent years, driven by rising global demand and expanding production capabilities. According to a report by the China Timber and Wood Products Distribution Association, plywood exports rose by over 10% in 2022, surpassing 22 million cubic meters for the first time. This surge is primarily fueled by a robust construction sector and a growing preference for eco-friendly building materials. Notably, the United States and European markets have become critical destinations for Chinese plywood, indicating a shift in trade dynamics.

Furthermore, the competitive pricing and increased variety of laminated plywood products are making Chinese manufacturers more appealing to international buyers. As highlighted in a recent study by Mordor Intelligence, the global plywood market is projected to grow at a CAGR of 5% from 2023 to 2028, with China expected to capture a significant share due to its efficient supply chain and strong export infrastructure. This trend not only reflects the growing importance of China's plywood sector in the global market but also positions it as a key player in sustainable construction initiatives, aligning with international efforts to prioritize renewable materials in various projects.

When it comes to selecting the right plywood laminated board for your projects, understanding the nuances between Chinese plywood and its global competitors is crucial. Chinese plywood is often celebrated for its affordability, making it an attractive option for budget-conscious consumers. However, the cost-effectiveness can sometimes come at the expense of quality, as variances in manufacturing standards and materials may lead to inconsistencies. Buyers must scrutinize certifications and quality markers to ensure they are making a sound investment.

Conversely, plywood from established global players often emphasizes higher quality and durability, driven by stringent manufacturing processes and superior raw materials. This frequently results in a product that performs better over time, ideal for projects that demand longevity. However, these advantages tend to manifest in a higher price point. Therefore, project specifications and budget constraints will play a pivotal role in determining the best choice. Crafting a well-informed decision requires comparing not just the price tags but also the performance and longevity expectations of each material.

When it comes to selecting the right plywood laminated board for your projects, understanding technical specifications is crucial. The primary specifications you should consider include thickness, veneer quality, and adhesive type. For instance, the American Plywood Association (APA) indicates that boards with a thickness of 1/2 inch to 3/4 inch are typically preferred for structural applications due to their enhanced strength and durability. Furthermore, veneer quality plays a significant role; selecting A-grade veneers can ensure a smoother finish and fewer defects, while lower grades may suffer from knots and inconsistencies.

Additionally, the choice of adhesive is paramount. According to a research report by Grand View Research, the demand for moisture-resistant adhesive systems is on the rise, particularly in regions with high humidity. These adhesives not only enhance the longevity of the laminated boards but also improve resistance against warping and delamination. By prioritizing these technical specifications, you can ensure that the plywood laminated board you select will meet the demands of your specific project, whether it’s for cabinetry, furniture, or structural elements.

| Specification | Description | Recommended Use |

|---|---|---|

| Thickness | Measured in millimeters (mm); ranges from 3mm to 25mm | Furniture, cabinetry, flooring |

| Grade | A, B, C, D grading; A is the highest quality | Visible surfaces, structural use |

| Core Type | Plywood core, MDF core, particleboard core | Balanced strength, weight considerations |

| Finish | Various finishes available including veneered, raw | Aesthetic applications, protection |

| Moisture Resistance | Standard, water-resistant, or marine-grade | Outdoor projects, humid environments |

| Weight | Varies by thickness and core type | Transportation considerations, project type |

In recent years, sustainability has taken center stage in the plywood production industry. Innovations are transforming traditional methods, emphasizing the importance of environmentally friendly practices. Manufacturers are increasingly sourcing timber from sustainably managed forests, ensuring that their raw materials are harvested ethically. This not only helps to preserve biodiversity but also combats deforestation and promotes responsible land use.

Furthermore, advancements in technology are leading to more efficient production processes. Techniques such as bamboo laminating and the use of recycled materials are becoming more prevalent, significantly reducing the ecological footprint of plywood. These innovations not only enhance the strength and durability of laminated boards but also make them more appealing to environmentally conscious consumers. As the industry moves forward, the intersection of functionality and sustainability will continue to shape the future of plywood products, paving the way for a greener and more responsible building approach.