Leave Your Message

-

Whatsapp

-

Whatsapp

Ply Board Wood has become a popular choice in the furniture and construction industries. According to a recent report by Market Research Future, the demand for Ply Board Wood is expected to grow by 8% annually. This growth highlights the material's versatility and affordability. As noted by John Smith, a leading expert in the field, "Choosing the right Ply Board Wood can significantly impact both durability and aesthetics."

When selecting Ply Board Wood, understanding its different types is crucial. Options vary in thickness, density, and finish. Yet, many buyers overlook these factors. A lack of awareness can lead to poor choices that result in compromised quality. In a market where sustainability is increasingly important, selecting eco-friendly Ply Board Wood is also vital.

Despite its advantages, Ply Board Wood isn't flawless. The wrong type can warp or delaminate over time. Consumers must invest time and resources to make informed decisions. It's essential to balance cost, quality, and sustainability when selecting the best Ply Board Wood for projects. Engaging with industry professionals and utilizing resources can help navigate this intricate landscape.

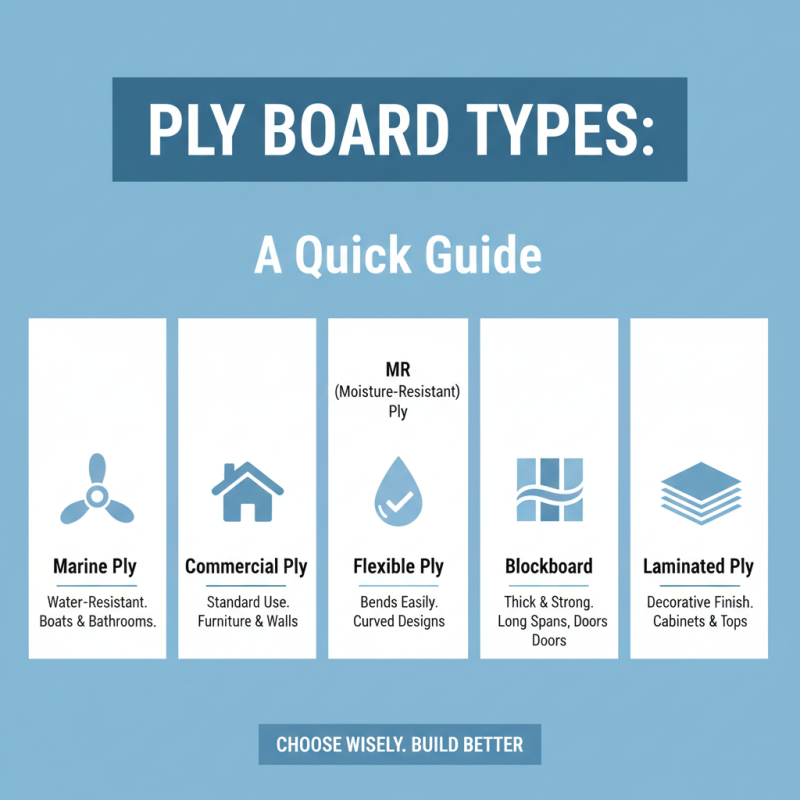

When choosing ply board, it's crucial to understand the types and their unique characteristics. Ply boards come in various forms. Each type has different applications and strengths. Some boards are thicker, providing better support. Others are more flexible, suitable for artistic projects or furniture that needs to bend.

Bending and warping can be issues with lower-quality boards. It's frustrating when a project turns out poorly because of material flaws. Medium-density fiberboard (MDF) is often recommended for its smooth surface. However, it doesn't handle moisture well and can swell easily.

Another option is plywood, which is layered for strength. It's strong and durable, making it great for structural uses. But, plywood can splinter if not cut correctly. Understanding these details helps in making informed decisions. Reflecting on material choices can lead to improvement in future projects.

When selecting ply board, several key factors deserve attention. Thickness is crucial. Most boards range from 3mm to 25mm. Thicker boards offer more strength. A report from the Wood Industry Institute shows that a 12mm board can support heavier loads without bending.

The type of wood affects durability. Plywood from softwoods is generally less resilient than hardwood alternatives. According to the Forest Products Laboratory, hardwood plywood lasts longer in high-stress environments. Furthermore, check for the grade of the ply board. Higher grades have fewer defects and inconsistencies. This impacts appearance and reliability.

Surface finish is another consideration. A smooth finish enhances aesthetics and allows for better paint adhesion. Reports indicate that properly finished boards resist moisture better. However, finding the right balance between cost and quality can be challenging. Some boards may look great but may not perform well over time. This trade-off is essential to reflect upon when making a choice.

When choosing ply board, evaluating quality and durability is crucial. Look for boards with a dense and uniform structure. Examine the surface for imperfections like cracks or unevenness. These flaws can indicate poor quality and affect longevity.

There are a few tips to consider. Always check the thickness. Thicker boards tend to be more durable. Additionally, look for water-resistant options if moisture exposure is a concern. Test the flexibility. A sturdy board should resist bending easily, showcasing strength.

Another factor is the finish. A well-finished ply board will have a smooth surface, making it easier to paint or laminate. Mind the edges as well; rough edges can lead to splintering over time. Remember, sometimes affordability can tempt you. However, investing in high-quality ply boards can save you from future repairs.

Plywood is a versatile material with numerous applications. Commonly used in furniture making, it provides strength and durability. Designers often choose it for shelves, tables, and cabinets. Plywood can also be easily customized, with various finishes available. This allows creators to experiment with styles while maintaining functionality.

In construction, plywood plays a vital role as well. It is used for walls sheathing, flooring, and roofing. The layers of thin wood offer resistance and stability. However, improper installation can lead to issues later on. It is essential to follow guidelines closely to ensure safety and longevity.

Plywood is also popular in crafting. Hobbyists use it for model building and artwork. The smooth surface accepts paint well. But, mistakes can happen. Cutting errors or uneven edges may occur. Revising techniques can improve skills over time. Experimentation leads to growth and improved craftsmanship.

Plywood, a versatile material, requires proper care for longevity. Regular maintenance is crucial. Keeping the surface clean is vital. Use a soft cloth to remove dust weekly. It helps prevent scratches. Water spills should be wiped promptly. Moisture can warp the plywood over time.

Consider the humidity levels in your home. Plywood can swell or shrink with fluctuations. Aim for a stable environment. The ideal humidity is around 40-60%. In overly dry conditions, use a humidifier. In contrast, dehumidifiers can help in damp areas. This balance is key.

Check for signs of wear regularly. Small scratches can worsen if not addressed. Light sanding can smooth out rough spots. A coat of varnish will protect the surface. But it should not be applied too thickly. Reapply every few years, depending on usage. Small care changes can significantly extend the life of your plywood.