Leave Your Message

-

Whatsapp

-

Whatsapp

Film Faced Birch Plywood is a versatile material widely used in construction and furniture making. This plywood has a smooth, durable film on one or both sides, enhancing its resistance to water and wear. Builders and designers appreciate its strength and aesthetic appeal. The fine grain of birch adds a touch of elegance to any project.

In recent years, the demand for Film Faced Birch Plywood has increased significantly. It has found applications in concrete formwork and temporary structures. However, it is essential to consider its environmental impact. Sustainable sourcing of birch trees remains a challenge for manufacturers. Balancing aesthetics with responsibility can lead to better practices in the industry.

When choosing Film Faced Birch Plywood, factors such as thickness, film type, and finish are crucial. Users often find themselves comparing options to meet specific needs. This decision-making process can be overwhelming. Striking the right balance between quality and cost is not easy, but it is vital for long-lasting results.

Film faced birch plywood is a versatile material. It consists of layers of birch veneer bonded together with a durable film on one side. This film offers excellent water resistance, making it suitable for various applications, especially in construction and furniture making. The plywood is lightweight yet strong, ideal for high-stress environments.

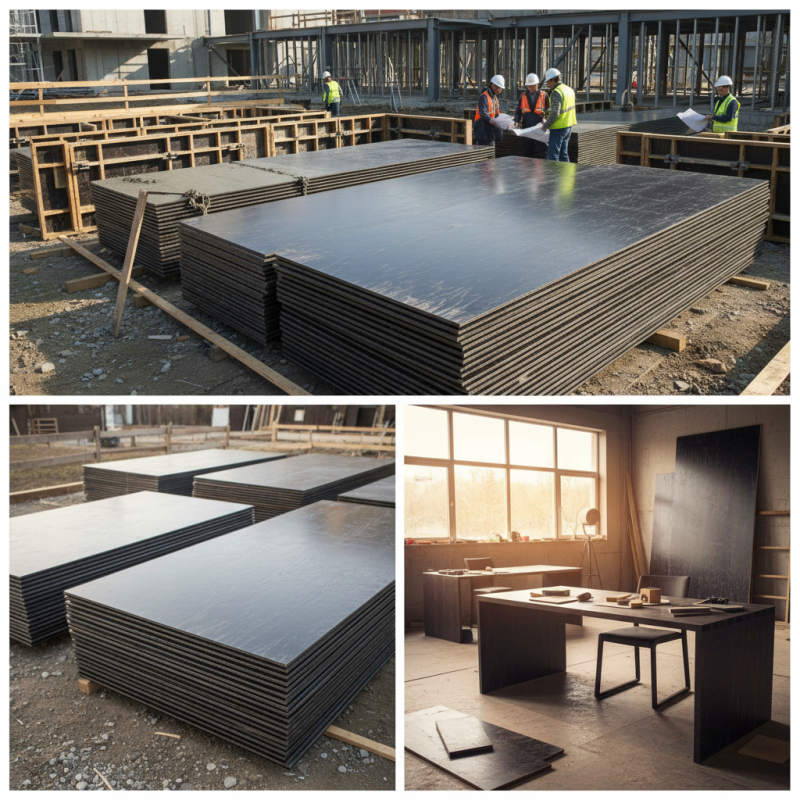

One can often find this plywood used in concrete forming. The film surface minimizes adhesion, ensuring smooth finishes. It is also popular in temporary structures due to its durability and ease of assembly. Consider using film faced birch plywood for applications where aesthetics and functionality are equally important.

Tip: Always check the plywood for defects before purchasing. Small imperfections may affect your project's outcome. When cutting, use sharp blades to avoid chipping. A little extra care can save you time and effort later. Aim for precision in measurements for better results.

Film faced birch plywood is known for its durability and versatility. Its composition starts with high-quality birch veneers. These veneers are glued together under high pressure. A film layer is then applied, which provides a smooth finish. This film is often phenolic, making it resistant to water and chemicals.

The manufacturing process involves several steps. Initially, logs are debarked and peeled into thin sheets. These sheets are dried to reduce moisture content. Next, layers are glued together using strong adhesives. The application of the film layer happens before the final product is cut to size. This entire process requires high precision to ensure quality. According to industry reports, the global market for plywood is projected to grow by 4.5% annually.

Despite its strengths, some challenges exist. For example, if not handled correctly, the film can delaminate. Furthermore, quality control is crucial throughout production. Minor flaws in layering can compromise the wood's structural integrity. Users should consider these factors when selecting materials for their projects.

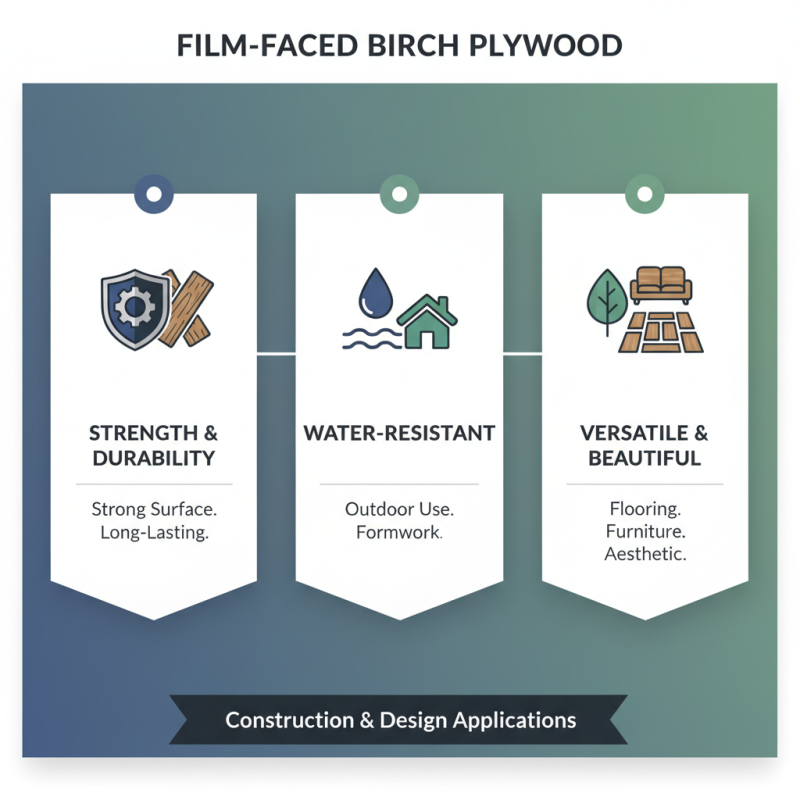

Film faced birch plywood is gaining popularity in construction and design. This plywood type is known for its strong surface and durability. The film on the surface provides water resistance, making it suitable for outdoor usage. It is often selected for formwork, flooring, and furniture. The natural beauty of birch adds an aesthetic touch.

One key property of film faced birch plywood is its strength. Birch is a dense wood, enhancing durability. This makes it less likely to warp or crack. Moreover, the smooth surface allows for easy cleaning and maintenance. It also resists scratches better than untreated wood. However, it can be challenging to find high-quality options. Lower grades may not perform as expected.

Tip: When choosing plywood, inspect the edges for any signs of delamination. It’s vital to consider your project’s requirements carefully. Another tip is to check the thickness needed. Different applications may require varying thicknesses for optimal performance. Remember to take your time when selecting materials. This can save you from future issues.

Film faced birch plywood is a versatile material widely used in construction. It is known for its durability and strength. This type of plywood features a phenolic resin film that makes it water-resistant. The smooth surface also facilitates easy cleaning, making it ideal for various applications.

One common application is in concrete formwork. Contractors appreciate its ability to create smooth finishes for poured concrete. It holds up well under pressure and exposure to wet conditions. There are drawbacks, though. The weight of the panels can make them difficult to handle. Care must be taken during installation to prevent damage.

In addition, film faced birch plywood is often used in scaffolding and temporary structures. It provides stability and support during construction projects. However, over time, the film coating may wear down. This can lead to increased maintenance needs. Projects should consider the trade-offs between initial costs and long-term durability when planning their use.

| Application | Description | Benefits |

|---|---|---|

| Concrete Formwork | Used as a mold for pouring concrete, allowing for smooth finishes. | Durable, water-resistant, and provides an excellent surface finish. |

| Cabinets and Furniture | Ideal for creating high-quality cabinets and custom furniture. | Strong, visually appealing, and easy to work with. |

| Temporary Structures | Commonly used in the construction of temporary buildings and shelters. | Lightweight, easy to assemble, and provides adequate protection. |

| Interior Wall Panels | Used for decorative and functional wall panels in buildings. | Aesthetic appeal, easy installation, and good insulation properties. |

| Flooring | Provides a strong and durable surface for various types of flooring. | Resistant to wear and tear, suitable for high-traffic areas. |

Taking care of film faced birch plywood is essential for its longevity. Regular cleaning is important. Use a soft cloth to wipe away dust and dirt. Avoid harsh chemicals that can damage the surface. A gentle soap solution works well for deeper stains. Make sure to dry the surface immediately after cleaning to prevent moisture damage.

Another crucial aspect is storage. Keep plywood in a dry, cool place. Avoid exposure to direct sunlight. This can warp the plywood or fade its appearance. If using it outdoors, ensure it is protected from the elements. A simple tarp can help. Inspect for any signs of wear and tear regularly. Small damages can be repaired before they become bigger issues.

Moisture control is vital. High humidity can lead to mold growth. Use dehumidifiers in damp conditions. Sometimes, despite our best efforts, the plywood might not look perfect. That's okay; it shows its character. Reflect on how imperfections can be a part of its journey. Every scratch tells a story, reminding us that care is a continuous process.