Leave Your Message

-

Whatsapp

-

Whatsapp

Choosing the right Ply Board Wood can be challenging. According to expert John Smith, "Quality Ply Board Wood makes all the difference in a project." This statement emphasizes how crucial it is to select the right materials for your needs. With a variety of options available, understanding the characteristics of Ply Board Wood can help you make an informed choice.

When considering Ply Board Wood, several factors play a role. These include thickness, density, and surface finish. Each of these elements can significantly impact the final outcome of your project. It's not just about aesthetics; durability and functionality matter too. Individuals often overlook these aspects, leading to regrets later on.

Many people assume that all Ply Board Wood is the same. This misconception can result in poor choices. Reflecting on your project requirements is essential. Take the time to research before making a selection. In doing so, you can ensure that your project meets the desired standards and lasts through time.

Ply board wood, or plywood, is essential in many projects. It comes in various types, each serving unique purposes. For instance, there are softwood and hardwood plywood. Softwood types are typically used in construction and general furniture. Hardwood plywood is stronger and ideal for fine cabinetry.

According to industry reports, the global plywood market is expected to reach $90 billion by 2026. This growth indicates the increasing demand for sustainable, high-quality materials. A significant shift towards eco-friendly products is noticeable. But not all ply boards are created equal.

There are also marine plywood and concrete formwork plywood, each designed for specific conditions. Marine plywood is resistant to moisture and rot. It's perfect for boats and outdoor projects. Concrete formwork plywood is used for casting concrete. This type needs durability and strength. However, the right choice can be confusing. Many overlook the quality grading system. Understanding these nuances can lead to better project outcomes.

Choosing the right thickness and density of ply board is crucial for any project. Most industry standards suggest that a thickness of 18mm is ideal for furniture making. This thickness provides strength and support while remaining manageable. Thinner boards, like 6mm or 9mm, can be useful for lightweight applications. However, they may not withstand heavy loads or impacts.

Density is another key factor to consider. The density of ply board directly impacts its durability. Higher density boards tend to resist warping and damage better than low-density alternatives. Studies indicate that a density of 600 kg/m³ is often favorable for structural applications. Yet, many overlook the importance of proper density, leading to projects that fail under stress. It’s essential to balance weight and strength based on the specific needs of each project.

Knowing how to evaluate both thickness and density can save time and money. Many workers have used mismatched boards, resulting in costly remakes. Examine your project's requirements carefully. Take time to assess the intended use of the plywood. Mistakes often stem from assumptions rather than facts. Proper research and attention to detail make a significant difference.

| Thickness (mm) | Density (kg/m³) | Best Use Cases | Pros | Cons |

|---|---|---|---|---|

| 6-9 mm | 400-600 | Cabinetry, Wall Paneling | Lightweight, Easy to Work With | Less Durable |

| 12-18 mm | 600-800 | Furniture, Shelving | Good Balance of Strength and Weight | Higher Weight |

| 19-25 mm | 700-900 | Heavy-Duty Applications, Flooring | High Durability, Excellent Load Bearing | More Expensive |

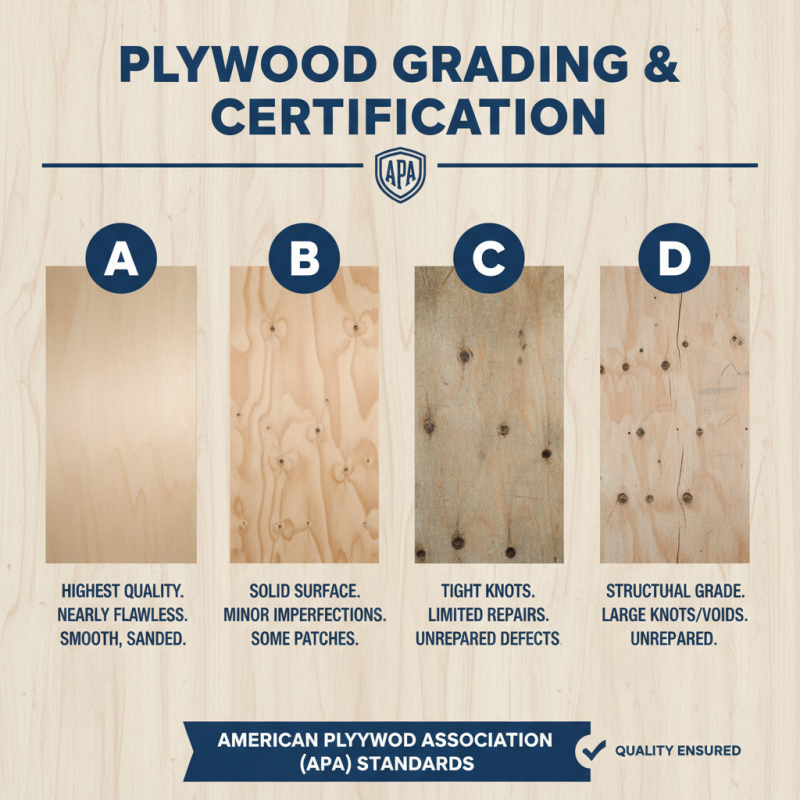

When selecting ply board for your projects, understanding grading and certification is key. High-quality ply boards are usually graded based on their appearance and structural integrity. The American Plywood Association (APA) grades the boards into categories like A, B, C, and D. Grade A is the highest, meaning it’s nearly defect-free. Meanwhile, Grade D boards may have knots and discoloration. This grading system is crucial for ensuring that the ply board meets specific standards.

Certification adds another layer of assurance. The Forest Stewardship Council (FSC) certification indicates that the wood is sourced sustainably. According to a 2022 study, products with FSC certification can attract up to a 15% price premium in the market. It’s important to consider certifications, as they reflect adherence to environmental regulations and quality control measures. However, not all manufacturers are transparent about their practices. Therefore, consumers must do their due diligence.

Some ply boards may look good on the surface but lack durability. For instance, a low-grade board might warp after some time, despite an appealing initial appearance. Understanding the nuances of grading can prevent expensive mistakes in future projects. Choose wisely; it impacts not just aesthetics but longevity and functionality as well.

When considering ply board for your project, evaluating costs is crucial. Reports indicate that high-quality plywood can range from $30 to $80 per sheet. Factors such as thickness and brand significantly influence prices. It's vital to assess your project requirements in relation to your budget. For instance, economic options might save money but could lead to durability issues later.

Another aspect involves understanding the cost of potential waste. A recent industry survey showed that on average, projects underestimated waste by about 15%. Choosing lower-grade ply may lead to more cuts and failures, unnecessarily driving up expenses. Proper planning can mitigate this risk.

Additionally, consider long-term costs versus initial investment. While premium plywood may seem costly upfront, its lifespan offers better value over time. Often, choosing the right ply board isn't just about the price tag today. Evaluate durability, potential repairs, and how it fits within your overall budget strategy. This reflection on costs is essential for a successful project outcome.

When choosing ply board wood, consider its environmental impact. Plywood is often made from various types of wood, sourced from forests. Unsustainable logging practices can lead to deforestation. This not only affects wildlife but also contributes to climate change. Always opt for plywood certified by environmental organizations.

Sustainability in ply boards involves more than sourcing. The production process itself can be harmful. Chemicals in adhesives may release toxins. These are harmful to both the environment and health. Therefore, look for products with lower emissions. Seek out alternatives that use natural adhesives.

There’s always room for improvement. Even eco-friendly products may have hidden downsides. Awareness is key. Educate yourself about where and how your ply board is manufactured. Transparency in the supply chain matters. It helps you make informed choices while reducing your environmental footprint.