Leave Your Message

-

Whatsapp

-

Whatsapp

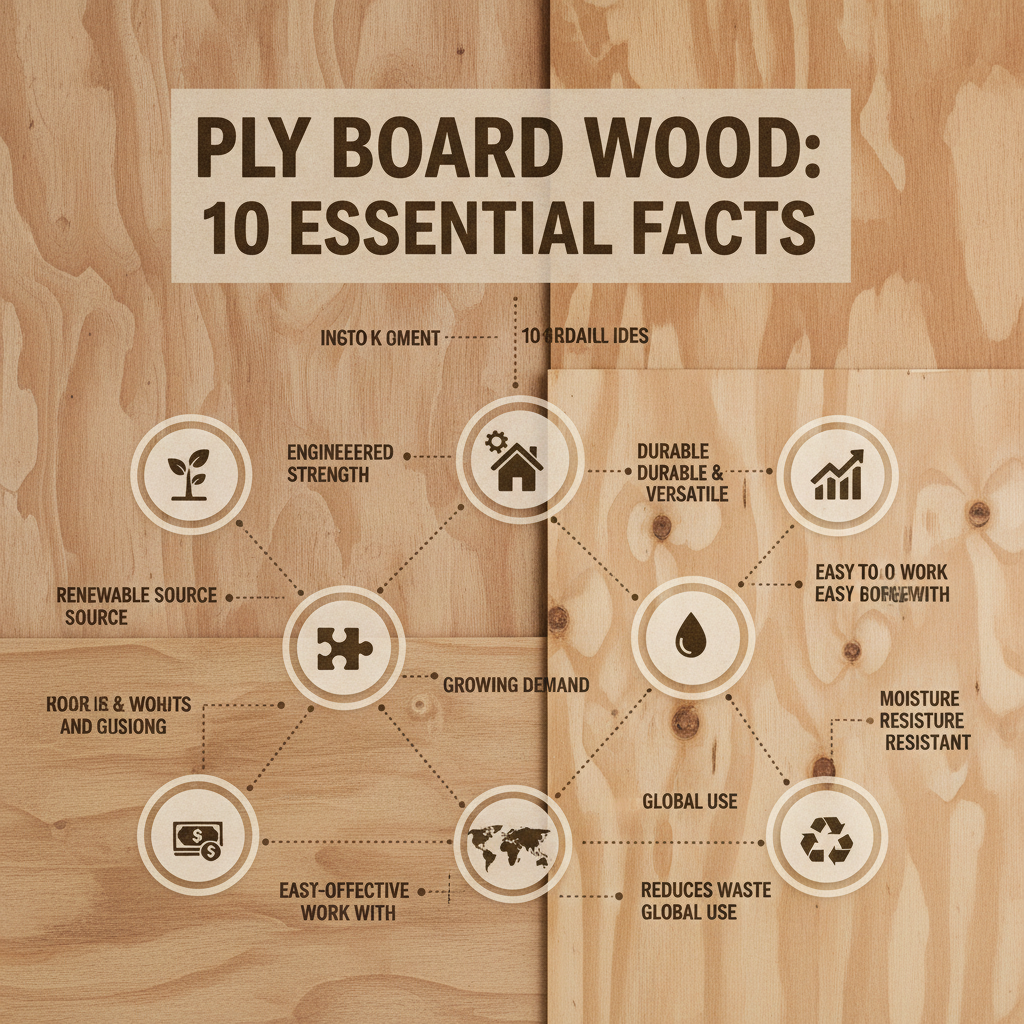

Ply Board Wood, a versatile engineered wood product, has gained significant traction in the construction and furniture industries in recent years. According to a report by the International Wood Products Association, the demand for engineered wood products is expected to grow by 7.5% annually, driven by their increasing popularity and sustainability credentials. Ply Board Wood, specifically, is renowned for its strength, durability, and aesthetic appeal, making it a preferred choice for both residential and commercial applications.

One of the key factors contributing to the rise of Ply Board Wood is its eco-friendly nature, as it is often made from renewable resources and utilizes fewer natural trees compared to solid wood options. A study published by the Forest Products Laboratory highlights that using engineered wood products can reduce deforestation rates and minimize waste, appealing to environmentally conscious consumers. As we delve into the ten essential facts about Ply Board Wood, it becomes clear how this material not only meets modern building standards but also supports sustainable practices in the wood industry, making it an indispensable resource for contemporary design and construction projects.

Plywood, often known as ply board, is a versatile engineered wood product composed of thin layers or plies of wood veneer glued together. The layers are usually arranged so that their grain runs perpendicular to each other, enhancing the material's strength and stability. Understanding the material composition of plywood reveals its renewable nature, as it is made from fast-growing trees, which contributes to its sustainability. There are various types of plywood, including softwood, hardwood, and marine plywood, each tailored for specific applications and environments, from furniture making to construction.

The plywood market is witnessing significant growth as a result of increasing demand in the construction and furniture sectors. Innovations in production, such as the development of flame-retardant adhesives and improved thermal performance traits, are enhancing the usability of plywood in diverse applications. This material is not just economical; it's also gaining popularity in modern interior design for its ability to provide aesthetically pleasing finishes at a lower cost. As more people appreciate its structural benefits and unique appearance, ply board continues to carve out a crucial niche in both residential and commercial spaces.

Ply board, also known as plywood, is a versatile building material commonly used in construction due to its remarkable strength and durability. Made from layers of veneer glued together, ply board is designed to withstand significant stress, making it an ideal choice for structural applications. Its layered construction not only enhances its load-bearing capacity but also provides resistance to warping and cracking, ensuring that buildings remain stable over time. This makes ply board particularly valuable in regions prone to varying climate conditions, where other materials may fail.

In addition to its mechanical properties, ply board is highly cost-effective. Compared to solid wood, it offers similar strength and aesthetic appeal at a fraction of the price. This affordability allows builders and homeowners to access high-quality materials without exceeding their budget, making it an attractive option for both small-scale renovations and large construction projects. Furthermore, the availability of different grades and finishes makes ply board adaptable to a wide range of design preferences, adding to its appeal in modern architecture.

| Fact | Description | Benefit |

|---|---|---|

| Strength | Ply board is engineered to provide superior strength compared to regular wood boards. | Allows for carrying heavy loads in construction projects. |

| Durability | Highly resistant to warping and shrinking, ensuring longevity. | Reduces the need for frequent replacements, saving costs. |

| Cost-Effectiveness | Offers a solid solution at a lower price compared to solid wood. | Ideal for budget-conscious projects without compromising quality. |

| Versatility | Can be used for various applications, including furniture, flooring, and wall panels. | Provides flexibility in design and construction options. |

| Eco-Friendly | Made from renewable resources and can be recycled. | Contributes to sustainable building practices. |

| Ease of Use | Can be easily cut, drilled, and shaped to fit specific needs. | Saves labor time and costs during construction. |

| Moisture Resistance | Certain types are built to withstand moisture and humidity. | Ideal for bathrooms and kitchens where moisture is common. |

| Fire Resistance | Some ply boards are treated to improve fire resistance. | Enhances safety in construction, meeting building codes. |

| Aesthetic Appeal | Can be finished with various veneers and paints for a polished look. | Increases the aesthetic value of construction projects. |

| Availability | Widely available in numerous sizes and grades. | Easy to source for any construction needs. |

Plywood, often referred to as ply board, is gaining recognition not only for its functionality but also for its environmental credentials. Sustainable sourcing is a cornerstone of modern plywood production. Many manufacturers prioritize wood obtained from responsibly managed forests certified by organizations such as the Forest Stewardship Council (FSC). This ensures that trees are harvested in a way that maintains biodiversity and ecological balance while supporting the livelihoods of local communities. Consequently, using sustainably sourced plywood contributes to forest conservation efforts and promotes a healthier planet.

Recyclability is another significant aspect of plywood’s environmental impact. Unlike many traditional building materials, plywood can be recycled and repurposed multiple times, reducing waste in landfills. The adhesive used in plywood manufacturing has evolved, with more manufacturers now opting for eco-friendly options that ensure the material can be processed at the end of its life cycle. Statistics show that recycled plywood can be transformed into new products, minimizing the need for virgin materials and further reducing deforestation pressures. This makes plywood not only a versatile construction material but also a responsible choice for environmentally-conscious consumers.

Ply board, also known as plywood, is a popular engineered wood product renowned for its versatility and strength. The industry distinguishes ply board grades based on various standards that correspond to its quality and intended use. The American Plywood Association (APA) provides grading classifications such as CDX, which indicates a combination of grades on the face and back veneer. In contrast, high-quality grades like A-A and A-B are typically reserved for applications that require aesthetic appeal and minimal defects, making them essential for furniture and cabinetry.

Understanding the different ply board standards is crucial for both manufacturers and consumers. For instance, the International Organization for Standardization (ISO) has established norms (ISO 3349) that guide the assessment of the durability and performance of plywood. Reports indicate that adhering to these standards not only enhances the longevity of the product but also reduces waste, with manufacturers achieving compliance often realizing a 20% reduction in costs associated with defects. Thus, staying informed about ply board grades and their corresponding standards is key for anyone looking to navigate the complexities of the wooden product market effectively.

Ply board wood is increasingly becoming a favorite in the realm of innovative architecture and furniture design. With its versatility, this engineered wood product can be molded into various shapes, allowing designers to create unique and functional spaces. The global veneer market is anticipated to grow from $16.36 billion in 2024 to $20.31 billion by 2032, reflecting a compound annual growth rate (CAGR) of 2.7%. This growth is fueled by the increasing demand for sustainable building materials and the aesthetic appeal of ply board in modern design.

One of the most compelling applications of ply board is in furniture design, where its lightweight nature combined with strength makes it ideal for creating elegant, yet durable pieces. Designers are increasingly leveraging its ability to be shaped, allowing for the crafting of intricate and customized furniture that meets both practical and artistic demands. Additionally, the trend towards open-concept living spaces has favored the use of ply board in partitions and shelving, offering a stylish solution that maximizes space while maintaining an airy feel.

**Tips:** When considering ply board for your design projects, look for options that emphasize sustainability, as eco-friendly materials are becoming more desirable. Ensure that your ply board is sourced from responsibly managed forests. Also, explore the numerous finishes available for ply board; a well-chosen finish can elevate your design while providing added protection.