Leave Your Message

-

Whatsapp

-

Whatsapp

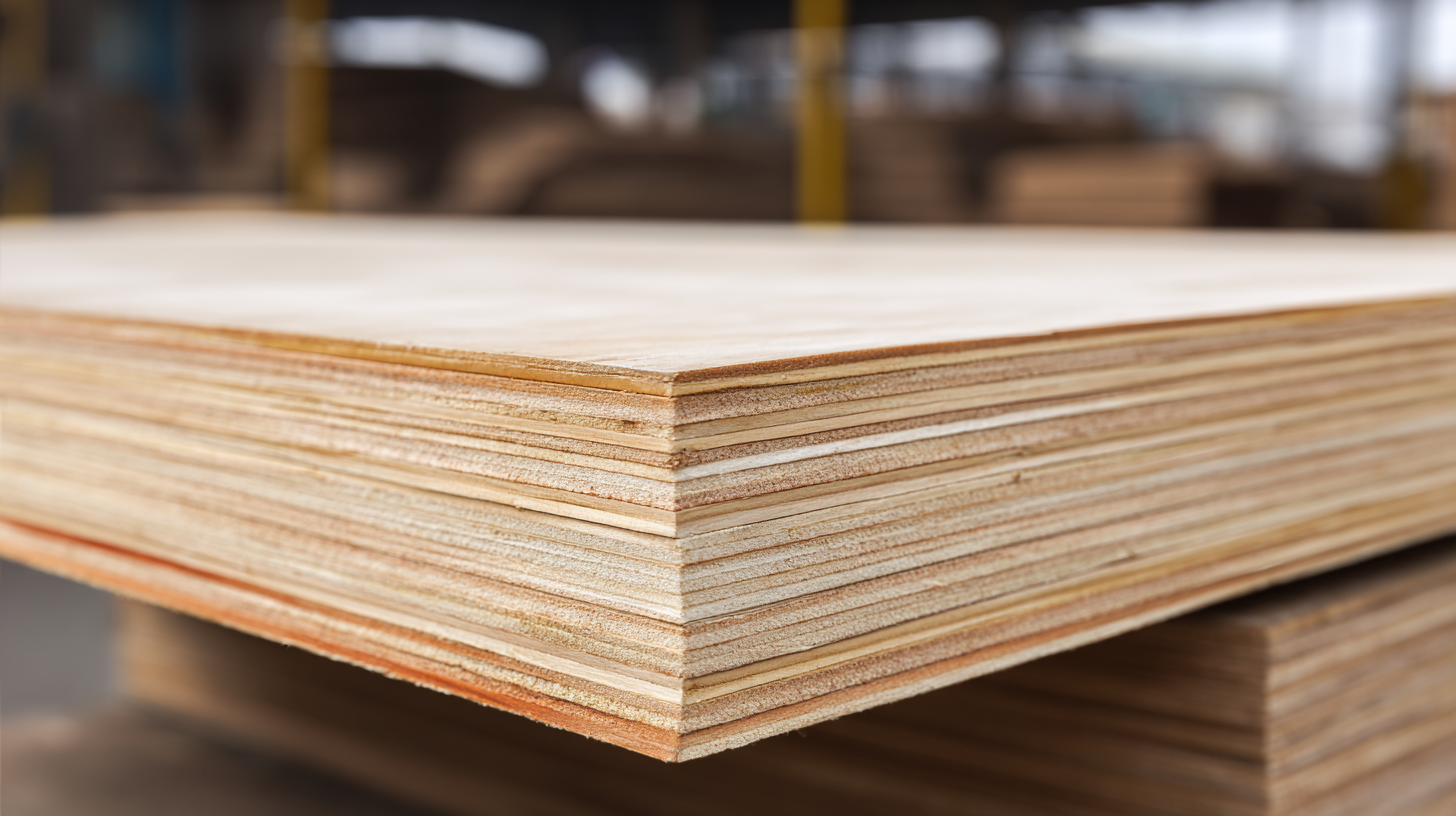

In the realm of construction, the choice of materials plays a pivotal role in determining the quality, durability, and aesthetics of a project. Among the myriad of options available,

Film Faced Birch Plywood has emerged as a frontrunner, offering unique advantages that are particularly suited for modern building requirements.

This specially treated plywood is not only robust but also designed to withstand the rigors of construction sites, making it a preferred choice for builders and architects alike.

One of the standout features of Film Faced Birch Plywood is its exceptional resistance to moisture and wear, which significantly extends its lifespan compared to regular plywood.

This makes it an ideal material for formwork applications, where reliability and performance are crucial. Furthermore, its smooth surface finish provides an immaculate result for concrete casting,

ensuring minimal finishing work is required post-construction.

As we explore the top ten benefits of using Film Faced Birch Plywood in construction projects, it becomes clear that this material offers more than just structural integrity;

it also enhances efficiency and cost-effectiveness, showcasing why it is a favored choice in today’s building industry.

Film faced birch plywood stands out in construction projects due to its exceptional durability, making it a preferred choice among builders and architects. The film overlay provides a robust barrier against moisture and weather elements, significantly enhancing the material's lifespan. This moisture resistance reduces the likelihood of swelling, warping, or delamination, which can compromise structural integrity over time. As a result, projects using film faced birch plywood can withstand challenging conditions, ensuring long-term performance and reduced maintenance costs.

In addition to its moisture-resistant properties, film faced birch plywood is known for its strength and resilience. The underlying birch veneer offers high tensile and compressive strength, making it ideal for heavy load-bearing applications. This inherent durability allows it to support various construction uses, from formwork to flooring, without compromising on safety or performance. Moreover, the smooth surface of the film faced plywood ensures easier installation and finishing, which is crucial for efficiency in construction timelines. This combination of durability and versatility makes film faced birch plywood an invaluable asset in any construction project.

Film faced birch plywood is a popular choice among builders due to its

cost-effectiveness in various construction projects. This specialty plywood combines

durability with an affordable price point, making it an attractive

option for both large-scale construction and smaller renovations. The film coating provides added protection against moisture and abrasion, which is critical

in environments where wear and tear are common. By investing in film faced birch plywood, builders can significantly reduce long-term costs associated with

repairs and replacements.

Film faced birch plywood is a popular choice among builders due to its

cost-effectiveness in various construction projects. This specialty plywood combines

durability with an affordable price point, making it an attractive

option for both large-scale construction and smaller renovations. The film coating provides added protection against moisture and abrasion, which is critical

in environments where wear and tear are common. By investing in film faced birch plywood, builders can significantly reduce long-term costs associated with

repairs and replacements.

Moreover, film faced birch plywood is easy to work with, allowing for faster construction timelines. Its lightweight nature makes it

easy to handle and install, which can lead to lower labor costs. Additionally, the plywood can be reused multiple times before showing signs of wear, which

further enhances its cost-effectiveness. Builders also benefit from the consistent quality and strength of

birch plywood, ensuring reliable performance in structural applications. This combination of affordability, durability, and user-friendliness makes film faced

birch plywood an essential material for construction projects seeking both efficiency and economy.

Film faced birch plywood is increasingly recognized for its eco-friendly properties, making it a popular choice in construction projects. This material is made from birch wood, which is sourced from sustainably managed forests. By using birch plywood, builders can help reduce deforestation and promote sustainable forestry practices. Moreover, the production process of film faced plywood minimizes waste and often utilizes low-emission adhesives, contributing to a lower environmental footprint.

Additionally, the durability and recyclability of film faced birch plywood enhance its green credentials. Its robust construction allows it to withstand harsh weather conditions and heavy usage, reducing the need for replacements and thus conserving resources over time. When the plywood reaches the end of its lifecycle, it can be repurposed or recycled, further minimizing waste in landfills. As the construction industry moves toward more sustainable practices, the adoption of materials like film faced birch plywood is essential in reducing environmental impact and promoting a greener future.

Film faced birch plywood is highly versatile, making it an ideal choice for various applications in construction projects. Its durable surface, coated with a film, enhances resistance to moisture and wear, allowing it to perform exceptionally well in environments prone to exposure. This resilience makes it suitable for formwork and scaffolding, where it can withstand heavy use while maintaining structural integrity. Additionally, the aesthetically pleasing finish of birch plywood allows it to be utilized in decorative applications, ranging from wall paneling to furniture design, adding both practicality and beauty to spaces.

Another significant advantage of film faced birch plywood is its lightweight nature paired with high strength, which facilitates easier handling and installation. This feature not only reduces labor costs but also accelerates project timelines. Furthermore, its adaptability to different cutting and finishing techniques means it can be customized to meet specific project requirements, whether for residential, commercial, or industrial structures. The ability to use the same material across various applications simplifies supply chain logistics and ensures consistency in quality and appearance throughout the construction process.

When it comes to construction projects, ease of handling and installation can significantly affect both timelines and overall project efficiency. Film faced birch plywood stands out as an excellent choice due to its lightweight nature combined with robust structural integrity. This plywood can be easily maneuvered by a small team or even a single worker, enabling quicker setups and reducing labor costs. The convenience of handling often leads to fewer workplace injuries, as less strain is placed on the workers during transportation and installation.

Moreover, the design of film faced birch plywood is user-friendly, featuring smooth edges and surfaces that facilitate seamless cutting and fitting. Its compatibility with standard tools makes it accessible for most construction teams, ensuring that installation remains straightforward and efficient. Additionally, the film overlay provides resistance to moisture and dirt, which not only prolongs the material's lifespan but also simplifies the cleanup process after installation.

This combination of lightweight handling and practical installation considerations makes film faced birch plywood a superior choice for modern construction projects.